Cars have become much nicer places to be over the last 40 years, thanks to huge advances in the technology used for engines, transmissions, suspension, body assembly and even styling to make them cut through the air more smoothly. But one of the biggest factors in making cars more comfortable has been huge advances is in-car insulation.

Years ago cars had basic bitumen sheets laid down over flat sections of the car’s floorpan and, much like the suspension and braking technology of the time, it was rudimentary and had limited effectiveness. It was stiff and brittle, and required heat to make it flexible but that would release toxins.

Today, we have far more advanced “constrained layer vibration damping sheets”, which are sometimes incorrectly mislabelled “Dynamat” (which is just one manufacturer of these products). Basically, modern sheet insulation is designed to cover the entire floor of the vehicle, as well as the door panels and even under the dash or in spare wheel wells. It provides a more flexible product that is far more capable at shielding the cabin from heat, as well as absorbing vibration and outside noise.

.jpg)

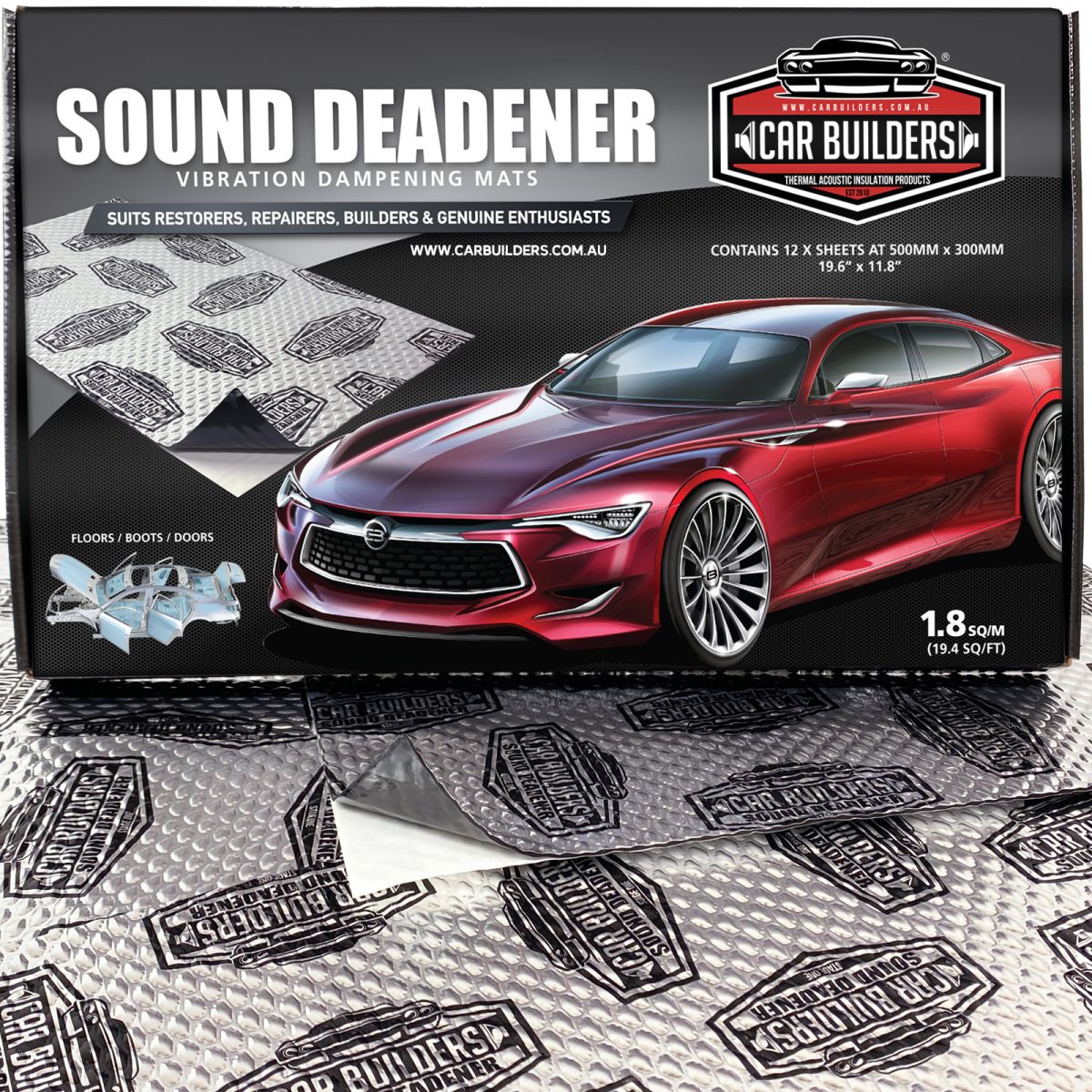

Car Builders Sound Deadener offers a highly advanced butyl-based peel’n’stick sheet insulation for vehicles old and new, which does not require heat to form, and comes with a hard-wearing aluminium top layer that adds yet another layer of heat resistance.

The Car Builders Sound Deadener doesn’t use an adhesive layer or need extra glue to stick down to the car, as the base material has been designed to seal straight to the metal. Some products use adhesive layer much the same as masking tape and can break down over time, allowing for moisture, which in time can lead to rust and deterioration.

Butyl-based damping sheets have been designed to not age, harden and get brittle, which can lead to the insulation cracking, which reduces its effectiveness. Car Builders Sound Deadener is designed to stick firm for the life of the vehicle, and is considered the Stage 1 of a multi-stage process to get the best thermal and acoustic insulation possible.

Sound Deadener is designed to be most-effective on any exposed single-skin sheet metal, like the transmission tunnel, foot wells, firewall, and rear bulkheads. Sold in sheets of 300mm by 500mm tiles the best way to ensure thorough insulation is to start in the middle of single skin sheet metal panels, then working out. Each box of tiles will cover approximately 1.8.m2.

The tiles have been designed in the 300x500 size to be the best compromise of workability around complex shapes, and having the best coverage possible. Tight areas will require the tiles to be cut to fit, though Car Builders also sells knifes to do this, along with a roller to ensure the tiles are fully stuck down with no air trapped underneath, and metal tape to seal the joins between tiles.

As a general coverage guide, one 1.8.m2 box will generally cover half a floorpan in a mid-sized car, while two boxes will cover where the carpet sits.